@2018安徽华艺生物装备技术有限公司

备案号: 皖ICP备05080771号 网站建设:中企动力 合肥

CopyRight©2017 滨州天虹电器有限公司 鲁ICP备10036012号-1 网站建设:中企动力淄博

CopyRight©2017 滨州天虹电器有限公司 鲁ICP备10036012号-1 网站建设:中企动力淄博

华艺卫生隔氧发酵系统

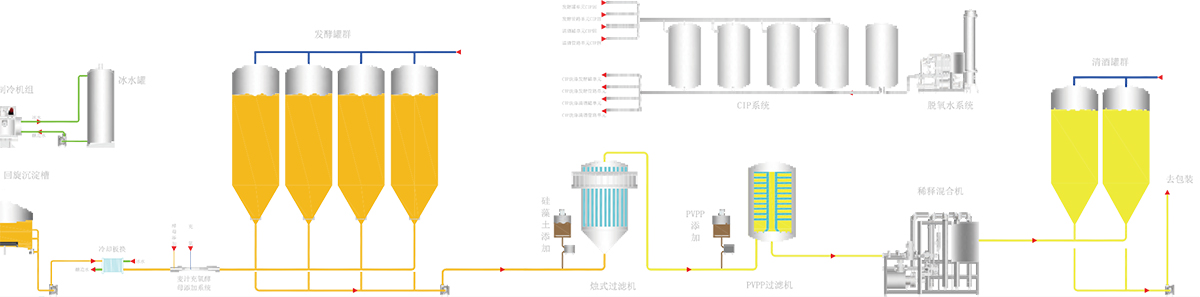

华艺卫生隔氧发酵系统 : 作为纯生啤酒时代的啤酒发酵系统,从发酵罐核心设备到发酵系统 CIP单元、麦汁充氧酵母机组单元、过滤单元、脱氧水机组单元、稀释混合单元、清酒单元以、阀阵管板单元以及工艺管线系统等系统的设计、制作及安装,无不体现卫生及隔氧的工艺理念。

Huayi sanitary oxygen-free fermenting system: As the beer fermenting system in the era of draft beer, the design, manufacturing and installation of fermenting wort oxygen-aerating and yeast unit, filtering unit, deoxygenated water unit, dilution mixer unit, bright beer unit, valve manifold pipe board unit and technological pipe system have displayed the technological concept of sanitation and oxygen isolating.